See more blog articles

Embrace outsourcing and fly

04 December 2023

Crack the outsourcing code and watch your business fly. The furniture industry is full of expert woodworkers and tradesmen making the very best furniture and interiors up and down the country, but there’s a downside to selling your skills by the hour, there’s never enough time in the day!

With a few small changes to your working habits, this situation can be greatly improved. Embrace outsourcing.

Set the scene

You know how it rolls, deadline pressures, a new enquiry you don’t want to miss, whatever the opportunity, you just can’t see how you’re going to fit it in. When work gets busy, it can be hard to ramp-up the pace without additional machinery or staff to use it, but with outsourcing, many of these issues melt away.

Solidify your profit

Overruns and mistakes can eat into the profit in any manufacturing environment. Buying your sheet materials already processed and on a fixed price gives you the confidence these costs are set in stone, allowing your margin to be added securely, without risk of it slipping away.

Time is money

Perhaps the biggest advantage of outsourcing is the time is saves you. While others are cutting your panels you can get one with something else, moving the project forward in other areas. Simply put, it allows you to complete more work within the same time frame.

How to get the most from outsourcing

Outsourcing takes forward planning. Most cut and edge services turn orders around in anything from a few days to a couple of weeks, so you need to have a final cutting list prepared early on. Those who are organised will find this bit a breeze, but we all know that one maker who works off a quick sketch and calculates cuts on the fly! Whilst it might work, this method isn’t so compatible with outsourcing.

It’s understandable to be nervous about your order turning up on time, especially on the first few orders. Trusting another company to dovetail with your schedule can take some getting used to, so it’s wise to build-in some extra time between receiving your order and putting it together. Something to bear in mind is most cut & edge companies work with people like you, so they are fully aware of how important a timely delivery is to you.

What’s the flip-side?

Life can sometimes throw a spanner in the works, so what are the risks with outsourcing? The risks are minimal, not least because professional cut & edge companies repeat their service day after day, so most of the creases will be ironed out. We could ultimately break the risk down into two groups, quality and timing. Maybe there will be a quality issue or defect on your order, or someone drops a panel and it needs replacing but the truth is, these risks are also apparent if you completed this work without outsourcing too.

Receiving a timely delivery might be the second most common worry. When you promise your customer an installation date you do not want to be let down by a 3rd party. Well, cut & edge companies think in the same way, and do everything within their power to get orders out as promised, after all, they want repeat business and that always relies on a happy customer.

A simple solution to cover-off these small risks is to plan your order a number of days before you need it. This allows for unforeseen issues to be resolved. If this isn’t possible, keep a good line of communication open with your supplier, they will tell you if your order is likely to be delayed.

Outsource Highlights

· Avoid costly mistakes and secure your profit margin on your sheet materials.

· Gain access to a huge range of large format materials and professional quality finishes.

· Buy yourself some more time. Complete more work in a shorter space of time.

· No need to hire more staff or buy expensive machinery to provide your customers with excellent products.

Submit your cutting list for a quote here today

Links to previous related blogs

2. Bespoke Shaker doors made to measure

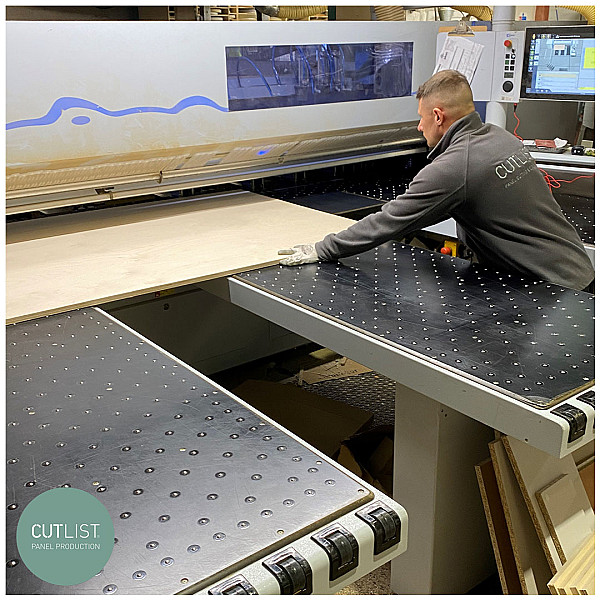

Industrial CNC machinery is often used by the cut & edge industry, providing a professional finish

Conclusions:

Outsourcing won’t suit everyone, but in a world where there is a skills shortage and employing people can bring a new level of management many wish to avoid, outsourcing provides and legitimate way of working to increase margins, revenue and output for more and more woodworkers across the UK. Tweak your working methods to suit, and you’ll never look back.

We asked our customers “What are the main results you’ve experienced after using [outsourcing to] Cutlist?”

“Just the convenience, makes everything easier. Basically, a member of staff”

“Made it allow easier to offer bespoke kitchens and wardrobes to clients”

“Definitely improved, there was a big time saving. Meant I could be working on multiple jobs at one time. Allowed me to take on more involved projects”

“Being able to plan fits because of reliability of Cutlist”

“The supply of Shaker doors has been a fantastic time-saver”

Written by Alex Langstaff-Ellis, Co-founding Director of Cutlist. December 2023

LOGIN

LOGIN